Why washing products in the poultry industry is not a waste of money. The benefits of washing products in the poultry industry

Consumers increasingly demand a produce that is safe and of higher quality. They also demand that the production process of the produces is sustainable, using fewer natural resources, like water and energy.

This is leading to an increased use of reusable plastic trays, crates, boxes, etc., for the transport of eggs and poultry meat. This increasingly use of plastic products requires, on the other hand, an increasing demand for correct washing and disinfection so that these plastic products can be reused in a safe and hygienic level.

Is washing a profitable operation in the egg industry?

At first glance one may consider washing a waste of money. A must, because regulations require it, but not really providing any direct added value. We easily see that when we grade and pack eggs or meat, there is a measurable added value and a related profit. The graded and packed product can be sold for a higher price than what was paid to the producer.

When we wash plastic trays or crates, we cannot see the immediately direct added value. The tray or crate is not more “valuable”. YET … if we have a disease outbreak in our organization, due to lack of biosecurity, we immediately see and suffer BIG related losses. Washing is then, recognized as a very profitable operation. ONLY when washing eggs …. can we see and measure the direct profit. For more information: For details on the benefits of washing eggs

How to increase the benefits of washing

To further increase the benefits of washing (safe and high quality food as well as increased bio security) you need to do it correctly and at the lowest possible costs.

What is required to do it correctly and at the lowest possible costs?

One can wash the products manually using one of the many pressure washers available in the market.

The required investment on the equipment is low, BUT:

- It is quite a labour intensive and un-pleasant work, which leads to difficulty to get & keep staff.

- It does not warrant optimal and consistent results (humans are humans!)

- It soils the area around the products to wash, requiring extra time and effort to clean it.

- It uses a high amount of water (it is a one-way water flow process.

- It does not warrent a complete washing and disinfection process.

- The number of products washed per hour is relatively low.

All in all, it results in HIGH operational costs and LESS THAN OPTIMAL results.

The use of washing machines warrants, despite the higher investment, a far better cleaning result and related food safety.

The correct washing machine warrants:

- Low labour requirements in a more pleasant environment (happier staff).

- Optimal and consistent results.

- Low water and energy consumption.

- Optimal rinsing and disinfection of the products

- Drying where it is required (optional).

Are then all washing machines good for you?

Not really. There are many washing machines available in the market, but you need to make sure you choose correctly.

How can you make sure that you invest in the most cost-effective unit?

What to look for when choosing your new washing machine? There are quite a number of features that help warrant that the unit provides the results you need.

Accessibility

A very important feature is accessibility to all sections of the unit.

The benefits are of high level of accessibility are:

- Easier operation of the unit

- Quicker and effective cleaning of the unit

- Quicker service of the unit

- … all in all higher effective operation at lower costs of time and labour

- "a machine that cannot be fully and thoroughly washed, cannot wash well"

Have you ever taken a bath in a dirty bathtub and came out clean?

OPTIMAL PERFORMING WASHING & RINSING SECTION

The following features play an important role in achieving the best results.

- Length of the washing section.

The longer the washing section is, the higher is the retention time the product will be effectively washed at a given capacity/speed. - The spray system – wash pipes and nozzles

Higher number of nozzles is important but it is also important that these nozzles are of different types and installed in different positions in the machine, in accordance with the specific surface of product to wash (side, top or bottom of product). Furthermore, it is important that the spray pattern defined by the manufacturer is not prone to be changed, and negatively affected, by operators, every time they clean the machine.

Spray system – pipes and nozzles – should allow quick and effective cleaning without requiring removal or disassembly. Keeping them clean warrants their optimal performance.

Filter system

The filter system should be specifically adapted to the specific cleaning objective and, at the same time, be easy to handle.

The more effective the filter is, the better the cleaning effect and the less amount of water and detergent will be used.

Water heating

Make sure you can choose the water heating system that suits your specific situation better.

Electrical heating elements, heat exchangers for connection to your hot water boiler or direct steam injection.

Rinsing section

It should allow the correct volume of water, at the right temperature, for a perfect removal of the rests of detergent and dirty that remain on the products after they exit the washing section.

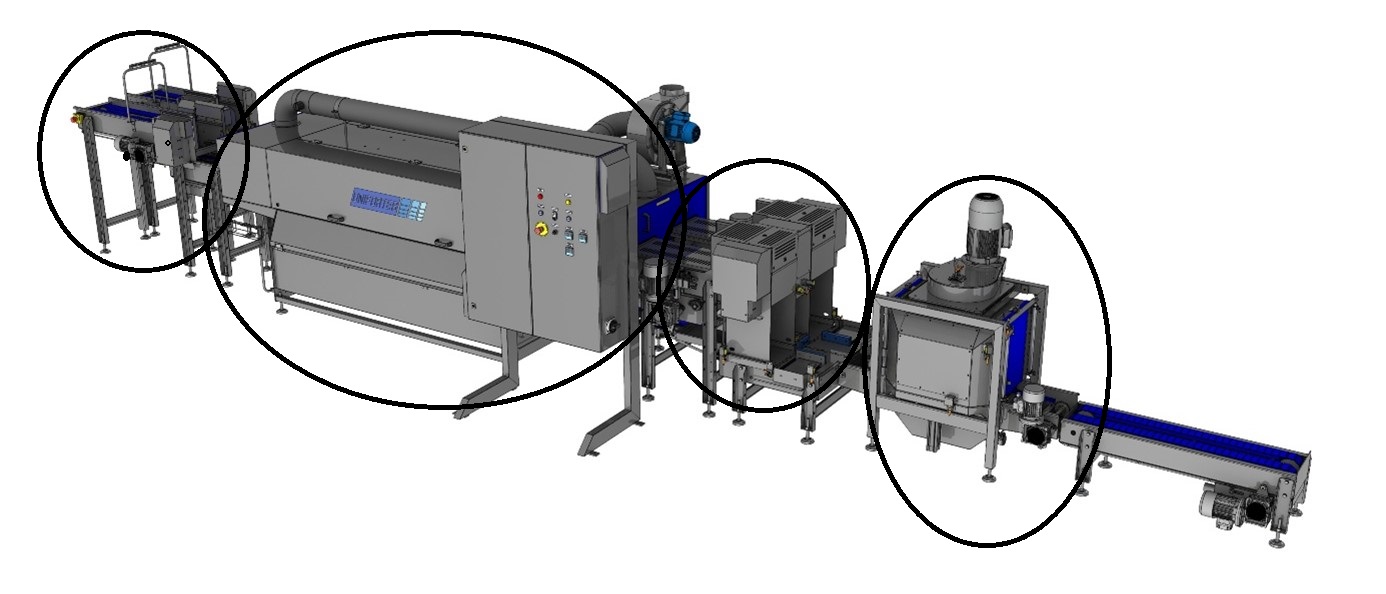

EFFECTIVE PRODUCT HANDLING SYSTEMS

Before and after washing, products may require a certain type of handling for more cost-effective operation.

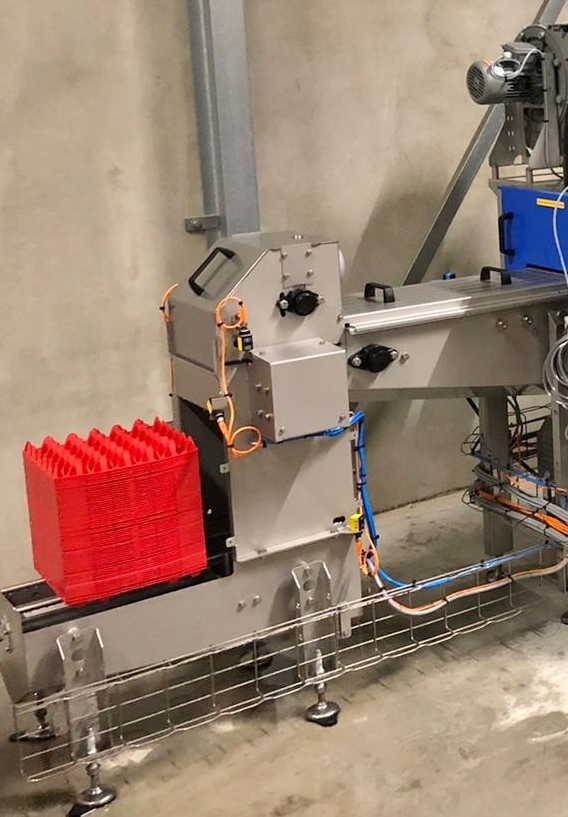

De-stackers, that automatically load the products one by one in the washing section.

Drying systems, that remove the water from the products to the desired dryness levels. Drying is possible using air blowers or spinning devices.

Stackers, that automatically make piles of the washed products.

Modular design

The market grows and your company grows with it. Higher capacities or other requirements are then needed, and it will be more cost effective that the equipment you choose can also be changed accordingly, without you having to trade it for a complety new unit.

ATTENTION

The above list of features is not final and definitive. It much depends on the type of products you need to clean, capacities required, etc., but it already gives you a good base for your search for the washing machine that best serves you.

Contact us at

READ MORE

EGG WASHING profit from the dirty eggs produced at your poultry farm

HOW TO WASH PLASTIC EGG TRAYS FOR THE POULTRY INDUSTRY